Fritsch

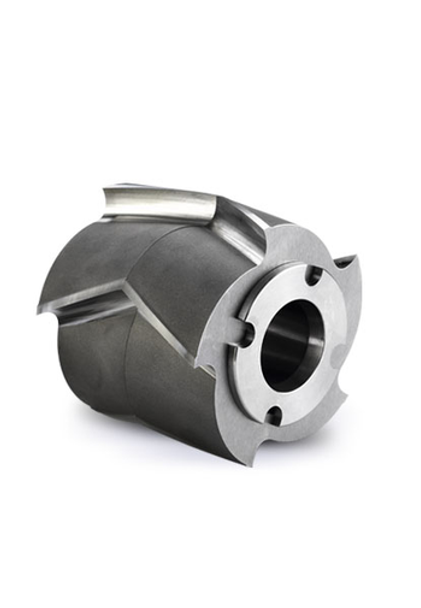

Standard Rotor with V-Cutting Edges and Fixed Knives Made of Hardened, Stainless Steel

- SKU:

- 45.5100.00

Description

The standard rotor made of hardened, stainless steel with V-cutting edges and fixed knives is suited primarily for comminution of tough-elastic materials and films due to its especially acute cutting angle and the high cutting action that results.

Alternatively, a rotor with V-cutting edges and fixed knives made of hardmetal tungsten carbide is offered. This rotor comminutes the grinding material through impact and cutting forces and is suitable for hard-tough materials.

We also offer a rotor made of hardened, stainless steel with straight cutting edges which run parallel to the fixed knives, it is suitable for easily cut material, such as hay, straw, fibrous or biological materials. The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

Additionally the especially robust disk milling cutter rotor with indexable inserts and fixed knives made of hardmetal tungsten carbide can even comminute scrap circuit board with glass fibre residue and copper cable. On the disk milling cutter rotor, the cutting plates can be turned four times and replaced individually. Damage or wear will never again make it necessary to buy a completely new rotor.

For the sample preparation according to RoHS (for the poof of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets made of chromium-free tool steel.

| Standard rotor with V-cutting edges and fixed knives | |

| General specifications | |

| Material | Stainless steel – 1.4112 |

| ISO/EN/DIN code | X90CrMoV18 / EN 10088 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 79 - 77 |

| Chromium – Cr | 17 - 19 |

| Silicon – Si | 1.0 |

| Manganese – Mn | 1.0 |

| Molybdenum – Mo | 0.9 - 1.3 |

| Carbon – C | 0.85 - 0.95 |

| Vanadium – V | 0.07 - 0.012 |

| Phosphorus – P | 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ ; |

| Hardness | 56 - 58 HRC |