Description

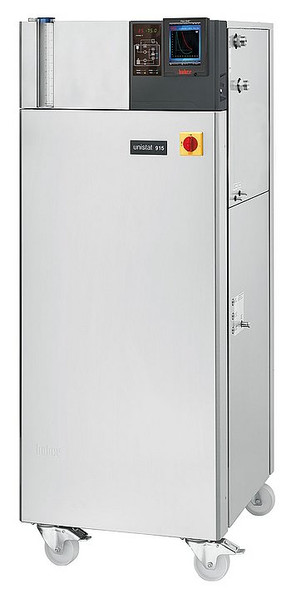

Unistat 915w

Dynamic temperature control system / circulation thermostat

Performance Characteristics

The Unistat range inspires with unique thermodynamic properties and a range of functions to meet the highest demands. Unistat technology guarantees precise, reproducible temperature control results, the shortest possible heating and cooling times and large temperature ranges without the need for fluid change. All Unistats are fitted with the innovative Pilot ONE controller with a 5.7“ touchscreen colour display and easy menu navigation. All important parameters can be seen at a glance and temperature curves are displayed in graphic real time.

Unistats are equipped with the most up-to-date pump technology for optimal heat transfer. The pump self regulates to ensure the best possible circulation and flow and delicate glass reactors are protected from breakage by the pumps soft start-up feature. Unistat technology impresses as a result of economic operation with reduced operating costs and efficient energy management. Because Unistats are hydraulically sealed, the service life of the temperature control fluid is dramatically increased by preventing oil loss through vapours and oxidation, further saving resources. Unistats are fitted with extensive safety equipment and are therefore suitable for unsupervised continuous operation. Relevant operating conditions are constantly monitored and the system is switched off if necessary or with the process safety feature the emergency cooling circuit is activated.

|

Operating temperature range |

-90...250 °C |

|

Temperature stability at -10°C |

0,01 K |

|

temperature set point / display |

5,7" colour Touchscreen |

|

Resolution of display |

0,01 K |

|

Internal temperature sensor |

Pt100 |

|

Sensor external connection |

Pt100 |

|

Interface digital |

Ethernet, USB (Host u. Device), RS232 |

|

digital input |

ECS ONE |

|

digital output |

POKO ONE |

|

Alarm message |

optic, acoustic, relay |

|

Safety classification |

III / FL |

|

Heating power |

6 kW |

|

Cooling power with |

Thermooil |

|

at 250°C |

6,5 kW |

|

at 200°C |

7,5 kW |

|

at 150°C |

9 kW |

|

at 100°C |

11 kW |

|

Cooling power with |

Ethanol |

|

at 0°C |

11 kW |

|

at -20°C |

11 kW |

|

at -40°C |

8,2 kW |

|

at -60°C |

4,2 kW |

|

at -80°C |

1,3 kW |

|

at -90°C |

0,6 kW |

|

Refrigeration machine |

water-cooled, CFC- and HCFC-free |

|

Refrigerant (ASHRAE, GHS) |

R-507 (A1, H280) |

|

Refrigerant quantity |

2,9 kg |

|

Refrigerant 2nd stage (ASHRAE, GHS) |

R-23 (A1, H280) |

|

Refrigerant quantity 2nd stage |

1,23 kg |

|

Circulation pump: |

MK pump |

|

max. delivery |

110 l/min |

|

max. delivery pressure |

1,5 bar |

|

Förderleistung bei 0,65 bar |

90 l/min |

|

Delivery at 1,0 bar |

74 l/min |

|

Delivery at 1,2 bar |

59 l/min |

|

Delivery at 1,4 bar |

31 l/min |

|

Pump connection |

M30x1,5 male |

|

max. permissible kin. viscosity |

50 mm²/s |

|

Cooling water connection |

G3/4 male |

|

Consumption at water 15°C, flow 0°C |

720 l/h |

|

min. cooling water differential pressure |

1 bar |

|

max. cooling water pressure |

6 bar |

|

min. filling capacity |

3,9 l |

|

Filling capacity expansion tank |

6,5 l |

|

Overall dimensions WxDxH ** |

630x704x1565 mm |

|

Net weight |

364 kg |

|

sound pressure level +/- 4 dB(A) |

64 dB(A) |

|

Power supply factory configured (3 Phase) |

460V 3~ 60Hz |

|

max. current (3 Phase) |

29 A |

|

Fuse (3 phase) |

3x32 A |

|

Pressure equipment category |

I |

|

Degree of Protection |

IP20 |

|

min. ambient temperature |

5 °C |

|

max. ambient temperature |

40 °C |