Description

CDO-28 Dry & Decarb Oven, 220V

Cascade’s CDO-28 is purpose-built for large-scale, industrial decarboxylation of material with additional features:

- 28 Cu. Ft.

- Built-in Humidity Sensor assists in dryness targets

- Stay in place sliding extension shelves

- NRTL Certification

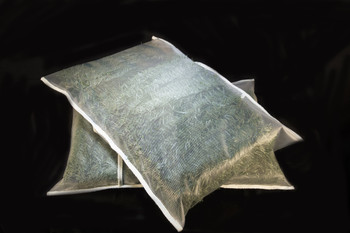

- 6 each FDA & temperature rated fine micron mesh bags for ground material – Mesh bags are required to prevent oven contamination and material loss.

This powerful, large capacity forced air laboratory oven uses heated air to remove unwanted compounds from products that are not temperature sensitive. Our ovens feature horizontal airflow that enables more consistent distribution of air. They are designed to have uniform temperatures and airflow across the shelf space from right to left.

The CDO-28 includes a built-in humidity sensor and fine micron mesh bags for drying or decarboxylating powders or ground material.

Ideal Uses:

- Industrial scale forced-air convection drying below 149ºC / 300ºF

- Decarboxylation processes

- Drying organic material. Drier material will yield better results than processing wet material. Removing as much moisture as possible pre-processing will save time in the post process of vacuum purge and winterization.

- Lab glassware dryer

Model CDO-28 Features

- Horizontal Airflow. The airflow moves uniformity across the shelf space from right to left

- Digital set-point control, timer and overtemp failsafe protection

- Humidity sensor displays relative humidity levels during process

- Includes 6 sliding, extend and stay in place shelves for ease of loading. Stainless Steel.

- Includes 6 temp-rated, fine micron mesh bags for easy loading & uniform drying of messy powders, ground up or turbulent materials

- Fast heat-up: 24 Minutes to 149ºC (300°F) / Uniformity: +/- 2ºC (3.5°F)

- Stainless steel interior / Food lab grade construction. 301 SST Shelves

- Triple wall construction meets CE, UL and TUV requirements to keep work-spaces cool.

- Quality Made in Oregon USA

- 1 Year Warranty

The Cascade Difference

Basic forced-air lab ovens are mass-produced and sold by many large scale laboratory equipment distributors. But there are key differences between Cascade and other less costly, often imported lab ovens:

Independent Overtemp Failsafe Protection

The Cascade Sciences CDO-28 is equipped with a heating cutoff system that will automatically stop power to the heaters when the overtemp setting is tripped. This protection system will provide peace of mind for overnight or unattended drying processing.

NRTL Certification. No Extra cost.

The CDO-28 Oven comes certified by the Nationally Recognized Test Lab, TUV. This certification is a requirement by many municipalities.

- CAN/CSA-C22.2 No. 61010-1:2012

- +UPD No. 1:2015-07 + UPD No. 2:2016-04

- CAN/CSA-C22.2 No. 61010-2-010:2015

- UL 61010-1:2012-05

- UL 61010-2-010:2015

- EN 61010-1:2010

- EN 61010-2-010:2014

Rigorous Quality Assurance in an ISO Certified, USA Manufacturing Facility

Cascade Sciences manufactures our ovens in Oregon, USA. We are proud of our ISO 9001 Certification/Accreditation. Each oven completes a series of quality assurance procedures before shipment:

- Electrical & mechanical safety is thoroughly tested in compliance with TUV requirements

- Functional testing verifies user settable items consistent with most lab protocols/usage models

- Temperature verification includes calibration & temp chamber uniformity following ASTM standards

- Units are cleaned and packed in ISTA tested, certified packaging materials

Model CDO-28

All shelves are removable and adjustable.

Capacity

Volume: 28 Cubic Ft. (793 Cubic Liters)

Interior: 31.5″W x 60.5″H x 26″D (800mm x 1,537mm x 661mm)

Exterior: 43”W x 85.5”H x 34.3”D (1,092mm x 2,171mm x 871mm)

Temperature

Temperature Range: 2.2ºC (36°F) above room temp to 148ºC (300°F)

Temp Stability: +/- 2ºC (+/-3.5°F)

Temp Recovery @ 240°F *Load Dependent*

Door Open 30 Seconds: 3 min to stabilize

Door Open 60 Seconds: 5 min to stabilize

Power Options 230V – 240V / 1ph / 26AMP |

Oven Must Be Hardwired By Electrician | Oven will also run on 208V

BTUs Per Hour at Max Power: 18,425 BTUs

Linear Shelf Space Airflow: 17.1 cubic ft per min

Air Intake Adjustable. Top 2.75” Diameter

Air Exhaust Adjustable. Top 2.75” Diameter

Shelving Comes with 6 each. Height adjustable. | Fits up to 16 shelves – buy more here

Surface Area: 31”W x 23”D (787mm x 584mm)

Weight Capacity: 75 lbs (34 kg)

Mesh Bags

Comes with 6 Temp Rated Mesh Bags | Fits up to 10 mesh bags – buy more here

Dimensions: 27.5″W x 21.5″D (699mm x 546mm)

Polypropylene (PP)

Melt Temperature: 161°C (363°F)

Softening Point: 152°C (305°F)

Heat Deflection Temperature: 90°C (194°F)

Glass Transiton Temperature: 0°C (32°F)

* Mesh bags are REQUIRED to prevent oven contamination and ground material loss.

* Polypropylene products produced for some filtration applications are made from resin that complies with FDA regulations for food contact. The regulation compliance is product number dependent / specific.

* Impact at cold temperatures is likely to cause strand cracking or breakage

Weight

Product Weight: 565 lbs (256 kg)

Shipping Weight: 640 lbs (290 kg)

Certifications

ISO 9001

NRTL TUV #U8 170464972 077

CAN/CSA-C22.2 No. 61010-1:2012

+ UPD No. 1:2015-07 + UPD No. 2:2016-04

CAN/CSA-C22.2 No. 61010-2-010:2015

UL 61010-1:2012/R:2016-04

UL 61010-2-010:2015

EN 61010-1:2010

EN 61010-2-010:2014